Intelligent agriculture has been regularly featured in agricultural-related discourses for the past 20 years. As technology is becoming more widespread, early speeches and visions are becoming real as equipment evolves and expertise grows. We are now at the point where smart devices are becoming more common as management tools. The BioDiPi-project of Oulu University of Applied Sciences investigated the intelligence of agricultural machines and their use. Jordi, who did his project work on the project, conducted a related survey that investigated the prevalence of ISOBUS bus use on the Spanish farms.

In intelligent agriculture, information obtained with the help of various sensors is used in farm management. Data is acquired with sensors integrated in the work machines during the work phases or with devices intended for separate data acquisition, which may be the farm’s own devices such as drones or data collected by satellites. The acquired data is used to control work machines or make decisions related to the care of production animals. To put it simply, intelligent farming is about putting input into the right place at the right time as accurately as possible.

When production inputs are placed in the desired locations, it will save money and environment. This can be seen, for example, in not fertilizing the entire field plot or spraying it with a plant protection product for safety reasons. In intelligent agriculture, a field plot is not considered as one large area of equal thickness, but as arable land divided into parts that need a different amount of production inputs in terms of productivity.

The way of working in agriculture has also changed and is constantly changing more. It is already possible to spray plant protection products from drones or to make a fertilization map using a field scanner integrated in the boom during fertilizer application. The information changes to a usable form. The communication between the tractor and the plant protection sprayer or other machine must be ensured and for this purpose the ISOBUS interface has been developed.

Case: ISOBUS and smart control

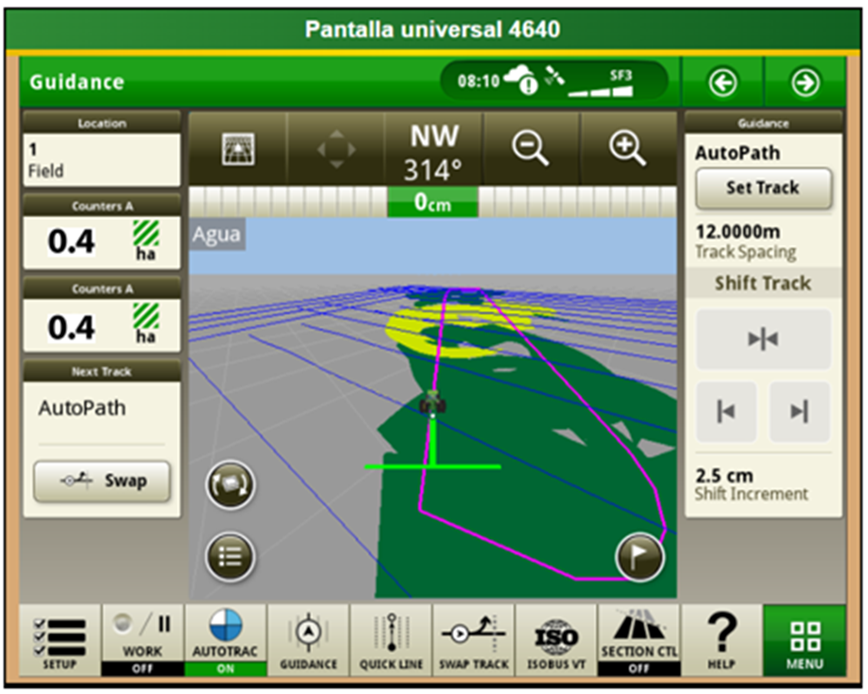

As mentioned in the previous chapter, the ISOBUS came out as a big revolution for farmers and agriculture for being able to transfer information between the implement and the tractor. ISOBUS system enables data transfer even if the tractor’s brand is different from the implement’s brand. Moreover, using it simultaneously with an antenna and a connected display, it offers possibilities to obtain maps. The maps that are being created at the same time the operation is carried out and they can be visualized through the tractor’s display. In addition to that, the maps can be analyzed in different layers including the speed and the doses applied. Thanks to the ISOBUS, the farmer knows the parts of the field that haven’t been worked and moreover just by looking at the screen. Overlaps can be avoided, which saves inputs and money.

After the operation has been completed, the data and the map are stored. The information can then be exported to a software, where the farmer can analyze it and get an idea of how the work has been done. The information can also be shared through social networks or directly with the clients.

The image 2 shows the creation of a prescription map. The field has been divided in different areas and each area has been introduced a different dose of herbicide application. After saving the changes, the prescription map is created as a file ready to be sent to the tractor’s display.

Other screenshot (image 3) was taken while the operation was being carried out. As can be seen, there is a lot of information highlighting the surface that is being worked, the different colors depending on the dose that is being applied according to the prescription map as well as the location of the tractor and the field boundary.

The tractor display is connected with the installed Modular-telematics gateway. It enables data transfer between them automatically. The data related to the work can be analyzed. The map of the dose applied, the speed carried and so on are created in different layers. If we compare it to the prescription map, we notice that they both are quite similar as the machine has adjusted automatically to the doses pre-established in the prescription map. Other information such as the duration of the work, the total amount of herbicide applied and so on. There’s also the option to edit some of the information and even add some notes. (Image 4.)

Results of the survey

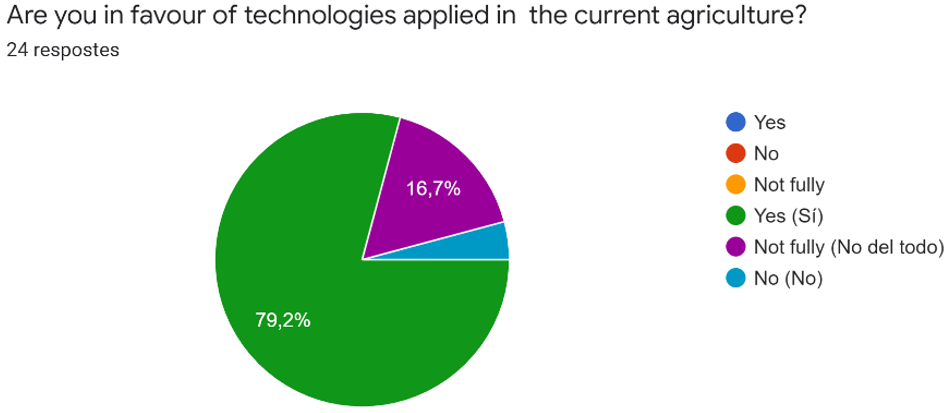

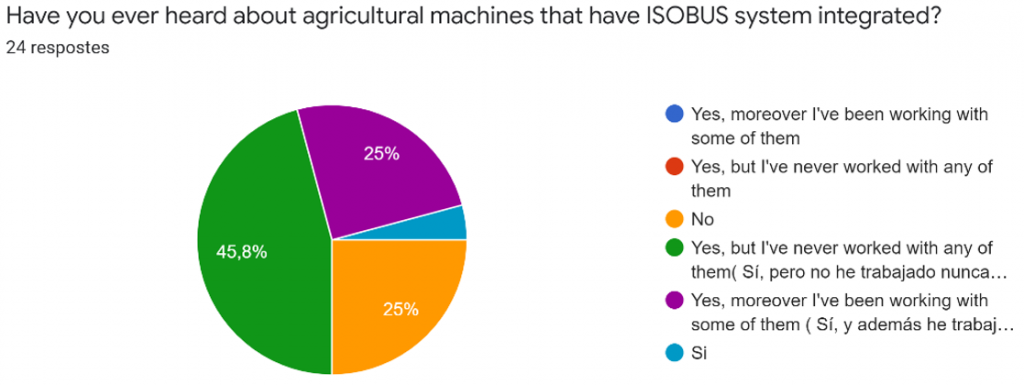

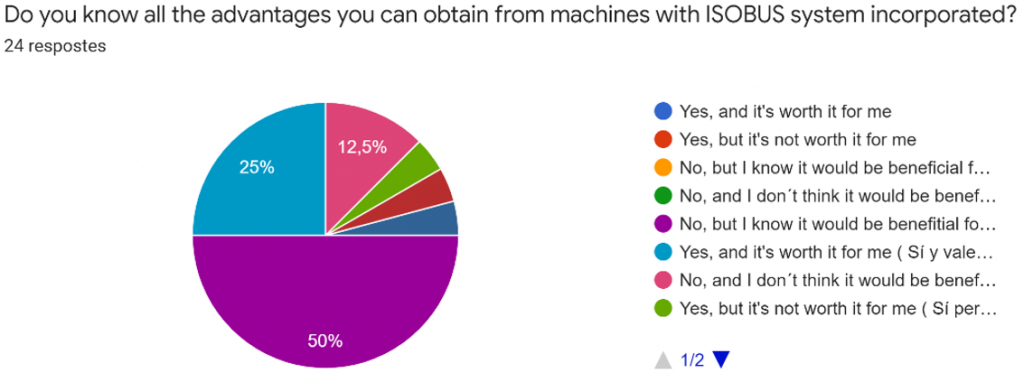

The survey has been made for John Deere customers in Catalonia, Spain to if they know how does it work, whether they have ever used implements with ISOBUS or not and their personal opinion about the way precision agriculture is evolving.

The results (figures 1–4) shows that the majority of people are in favour of technology applied to agriculture despite that most of them haven’t worked with ISOBUS implements. However, half of the survey respondents affirm it would be really beneficial.

From the last part of the survey we can conclude that the most used implement is the sprayer gun (figure 4).

It is worthwhile to utilize data

Thanks to new data collection systems, farmers can make decisions about field work before they start working. They can use the information acquired with the drone or satellite, which controls precisely the tractor’s actions in the field with the help of location information.

Modern tractors have multiple functions to optimize the operations carried out in the field such as ISOBUS technological system. This system enables the activation of several tools to save inputs and avoiding overlappings. Therefore, it entails a higher efficiency as more work can be done in less time and saving of inputs.

Mikko Posio

Lecturer

Oulu University of Applied Sciences, School of Engineering and Natural Resources

Jordi Melgosa Valls

Agricultural and Food engineering student

Oulu University of Applied Sciences

Universitat de Lleida (UDL), Catalonia, Spain

Vastaa

Sinun täytyy kirjautua sisään kommentoidaksesi.